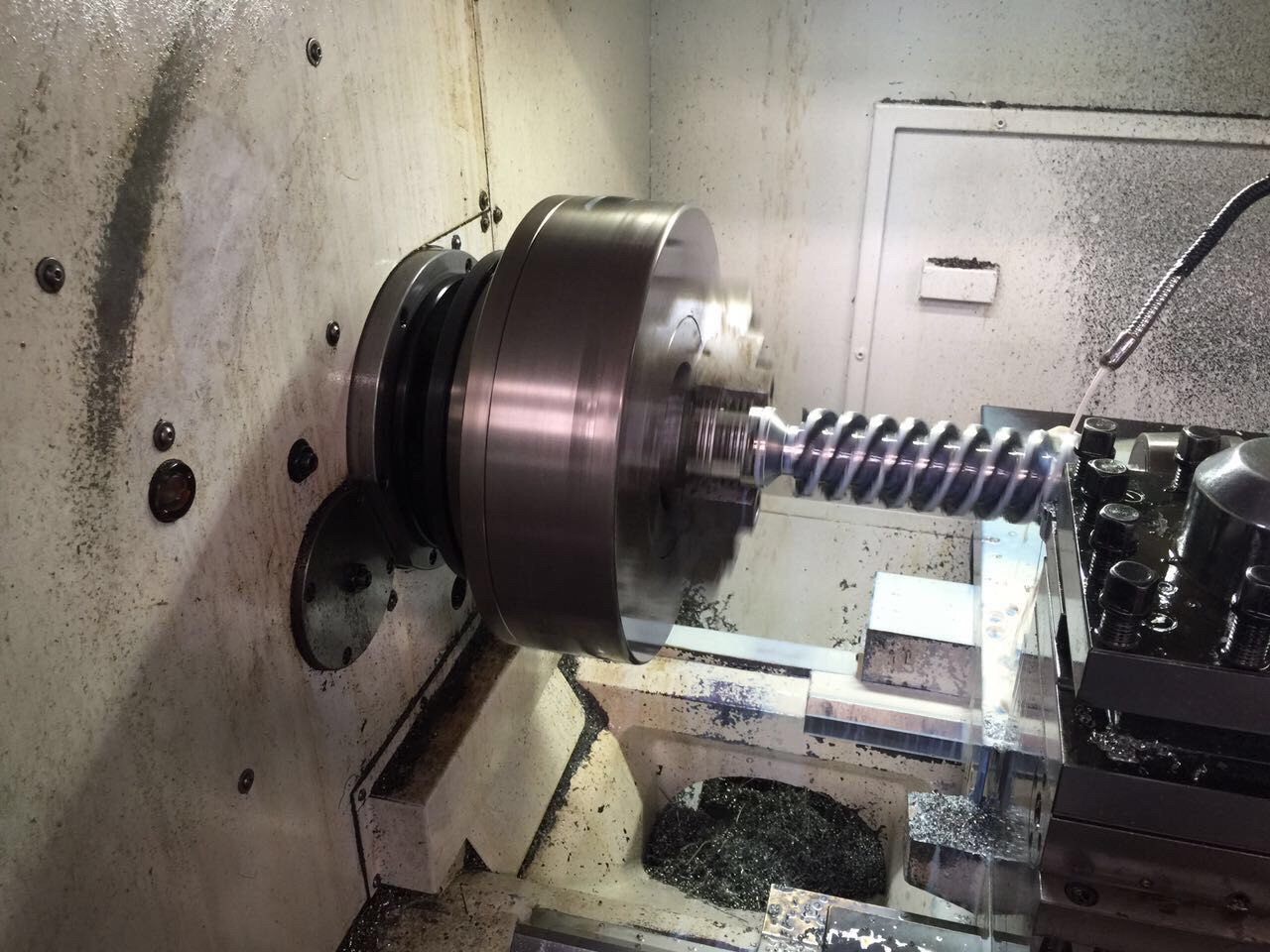

US Castings dedication to Value-Engineered principles, in conjunction with its Engineering Department and top-tiered suppliers, remains highly confident in its ability to deliver a superior product at a competitive price. The U.S. based sales and logistics team is dedicated to removing the stress that can often accompany the tribulations of dealing with 3rd party suppliers.

To demonstrate this commitment, a Zero-Risk policy has been implemented, which puts the ownership of Quality Assurance, Quality Control, and on-time delivery, on the shoulders of the US Castings’ Management Team.

Details of the Zero-Risk policy:

Delaying payment until delivery is hardly risk free if a rejection delays the production schedule. US Castings will provide extra engineering and support at the front end of the process to ensure total customer satisfaction in the production phase.

With a customer driven focus on Value-Engineering, the cornerstone of US Castings’ philosophy, experts from the engineering and production divisions will work to help identify potential cost savings through grade selection, manufacturing methodology, and optimization of the final product design.During the mass production phase, US Castings’ highly experienced Quality Assurance team is thoroughly checking that materials meet the customer’s designs, providing input, and noting proper documentation as required.Benefits to US Castings customers: